General Electric

FM MOBILE RADIO HISTORY

Part One, 1940 - 1965

PAGE TWO

1960's And Later Equipment

TRANSISTORIZED PROGRESS LINE (1959-1965)

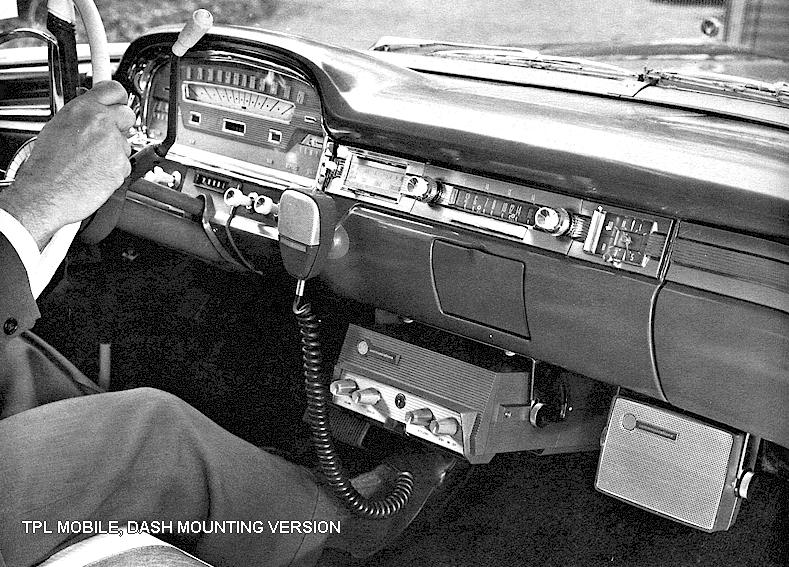

GE's entry into the market of the 1960's was the Transistorized Progress Line, or TPL equipment, although production of the Progress Line continued simultaneously for a few years. All manufacturers were in a race to produce equipment which was as transistorized as possible, and at that time this meant using germanium transistors. Because of this race, some less-than-optimum implementations or processes were sometimes rushed into production. GE's TPL consisted of a fully transistorized receiver and a partially transistorized transmitter, in a modular housing which could be taken apart and mounted throughout a vehicle in separate pieces. The TPL was initially supplied as a rather large under-dash package consisting of a front section containing the receiver and part of the transmitter exciter, a center section containing the balance of the transmitter exciter and a power amplifier, and a rear section containing the power supply for the transmitter, as shown in the first photo below. A complicated engine-compartment mounted fuse-block relay unit switched power to the power supply section and muted the receiver, something done internally in Motorola and competitive equipment.

TPL shipments began in approximately late 1959. For some reason, most TPL's seem to have been made in 1961-62, at least in my observation of used equipment. The TPL was officially first announced at the Forestry Conservation Communications Association meeting in Hot Springs, Arkansas in July, 1959.

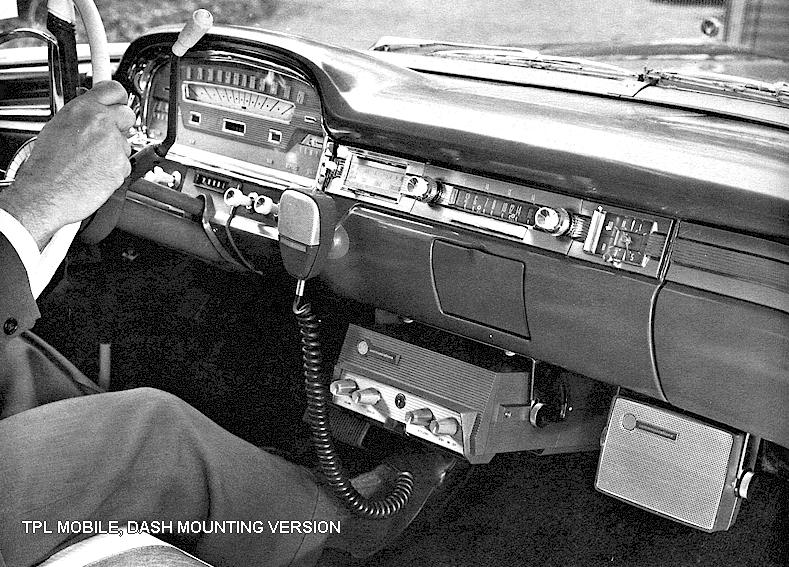

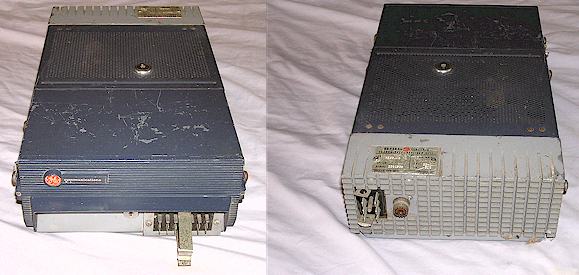

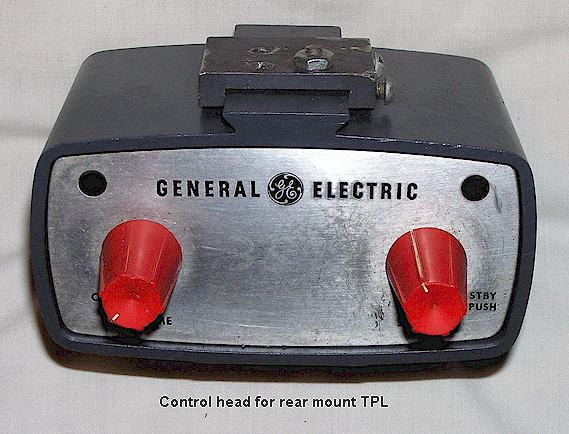

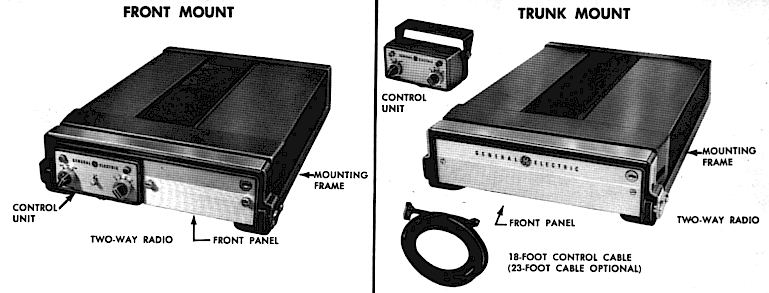

There was an optional cable and bracket kit which allowed the dash mounted receiver to be separated from the rest of the unit in an ugly, impractical and unreliable arrangement which then resulted in the creation of a trunk mounted mobile with an oversized control head. This led to the somewhat incorrect perception in the industry that the TPL had "the receiver contained in the control head." A third arrangement which seems to have been developed a year or two after introduction, finally placed all sections of the TPL into a trunk mounted package and supplied a conventional, quite small control head with just volume and squelch controls inside it. In all versions, the open ventilation of the transmitter exciter and power amplifier section subjected them to dirt and moisture intrusion to a greater extent than enclosed radios. As a matter of trivia, there were some issues with poor contact to the pins of the Cinch-Jones style main control connector on the front of the trunk-mounted style TPL, resulting in a re-designed cable connector retainer clip assembly and probably resulting in the replacement "MASTR Professional" series using a round-pin connector of proprietary GE design.

TPL equipment was only made in VHF low and high band models. There was no UHF TPL. The UHF counterpart to the TPL was probably the Accent 450, although the Accent was introduced more toward the mid-1960's. TPL offered many unusual options, such as dual front ends and noise blankers, most of which were added underneath the equipment in ugly accessory housings, connected by unique and proprietary connectors. The high band TPL was introduced first, in 1959, while the low band versions were introduced in June, 1960.

The speaker in the TPL series contains the radio's final audio amplifier as well. This was a theme of the early 1960's also used other manufacturers such as RCA in its first hybrid equipment (Super Carfone series.) There were two speakers available, a 2 Watt and a 10 watt model. The 10 Watt speaker was supplied with a coiled cord and the unique feature of a lip on the rear edge to allow it to be removed from its bracket and placed on a vehicle window so that it could be heard by workers away from the vehicle. This feature was generally not seen again on later GE equipment although Motorola thought enough of it to copy the lip on the housing of their Micor line of speakers in 1970.

The TPL used a number of proprietary items such as the connectors for the microphone, relay assembly and speaker, which were never seen again on any other GE equipment. There were two styles of microphone connector for the Shure made microphone - - a disposable rubber-style one molded with the cord, and a re-usable metal bodied version. The housings were made from a surprising number of elaborate die castings, in shapes quite unusual compared to other equipment in the industry.

Also surprising was the use of sockets for the transistors, something not seen on competitive equipment, and one of the downfalls of the TPL. In rough service, it was reported that it was not unusual for technicians to pull a defective unit for repair only to find several of the transistors rolling about loose in the bottom of the receiver housing! Apparently the reliability of the transistor was not anticipated, and the designers chose to treat them like vacuum tubes, making them plug into sockets, but without any retaining hardware.

The high band receiver in the TPL was produced in two models. The original receiver used a coil and capacitor L-C tuned circuit "front end," while the last-generation TPL used a helical resonator front end. The exciters also went through two models. The early exciters contained a sealed delay-line modulator module, while the later ones were improved with a more conventional design. Either TPL transmitter modulator has excellent audio. A 10 Watt TPL mobile could be made into an 80 Watt model by plugging an 80 Watt power supply and transmitter module onto the receiver/control/exciter section.

The TPL was plagued with numerous problems which have generally relegated it to the category of one of the largest design failures in the history of two way radio, although some of this criticism was in retrospect unfair. The plug-in transistors fell out of their sockets, as mentioned, and in my experience the solder joints of the stiff wires connecting the two opposing circuit boards in the receiver section could develop cracks. The early models were somewhat sensitive to vehicle battery voltage variations causing the squelch threshold to vary. The complicated cabling was an installation nuisance of major proportions.

On the other hand, the TPL had a number of unique performance advantages. When squelched in stand-by, it drew less current than a single pilot lamp, about 50 ma., allowing it to be left on at least overnight in a vehicle, if not permanently, depending upon the level of radio traffic and the setting of the volume control. Even today's equipment can not make that claim. Unlike the standard Progress Line, the TPL control head featured a stand-by switch which switched off the transmitter's tube filaments to save current, as well as the green "on" pilot lamp.

Ray Minichiello, who retired as GE's Manager of Product Planning, Communications Products Department, was with the company at the time the TPL was in production, and shares the rare inside story that the TPL's initial problems were not the fault of its electrical design. It seems that the transistors used in the TPL were primarily supplied by GE's Transistor Department in Syracuse, New York. In Ray's own words:

When high rates of transistor failures in the field were reported to the Transistor Department, it was but a puzzle as other customers of the same type transistors enjoyed 100% reliability. The relationship between the two departments soured to include threats of switching to Motorola products! The Syracuse gang requested a hands-on following of each operation on receipt of the transistors, inspection and preparing, including the process of installation in the board...

The Syracuse engineers discovered that after receipt of the transistors at Lynchburg Receiving Section, the transistors were inserted in a device to cut the leads to the proper length. However, it was discovered that the device pulled the leads during the cut, only to fracture the internal junction! When the transistors were inserted in the finished product, it was only a matter of time that the junction dislodged, resulting in failure of the TPL. The Methods man quickly modified the design of the lead cutting tool and thereafter TPL's enjoyed a high reliability reputation. However, it was regretfully long after the first shipments of the TPL to the field and the product was already subject to a bad "rap."

Accessory decks were added to the TPL between the receiver section and the exciter, such as the Channel Guard board. Yet additional decks were added underneath, such as the noise blanker and the dual front end sections, making a rather bulky package. Note that the front (receiver) section is connected to the rest of the chassis solely by two coaxial cables with RCA connectors, the DC voltage being superimposed onto the cabling.

The majority of TPL's seem to have been made in VHF high band models, and they were purchased in large numbers by the US Government and the Bell System. TPL production ended in approximately 1965, representing one of GE's shortest-lived mobile radios. If nothing else, it was certainly an unusual and attractive set in the dash mount configuration.

At a sales meeting in 1962, GE announced the "Ruggedized TPL." I have no idea what this consisted of, other than possibly the new helical resonator receiver front end deck and a re-designed rear-mount connector fastening system.

Shown below is a rear mount

version of the TPL, in a 35 Watt configuration:

Unusual and rare 4 Frequency TPL rear mount control head:

SIREN AND PA EQUIPMENT

During the development of the TPL line, a transistorized mobile PA amplifier was developed. This too used socketed small signal transistors, while the main amplifier DS501 style transistors were hard wired into the circuit. These amplifiers were initially available as the model series 4EA5, which was apparently intended mainly as an accessory to the Progress Line and is specified as a 20 Watt unit. Later models were the 4EA12, as shown here, which seems identical to the 4EA5 other than having a TPL series microphone socket as an option and shows a 25 Watt output. 25 Watts was not very much power for a siren, and it seems as if few of these were sold. I recently acquired the example below, which is the first one I have seen in 50 years of collecting. The original model 4EA5 was originally only a PA amplifier, the faceplate did not have the center switch. There was a field modification kit for adding the siren feature, which among other things involved replacing the faceplate and adding an additional circuit board. The 4EA12A10 was the PA-only model while the 4EA12B10 was the model shown below, with the the siren.

To see the original GE sales sheet, click here

PACER AND ACCENT 450

Pacer and Accent 450 are grouped together as they were both economy radios built for a short period of time. The desktop base station versions of them appear similar.

PACER (1961-1965)

Pacer was a VHF economy all-tube under-dash radio which used printed circuit boards with tube sockets mounted on them, introduced in January, 1961. It was an approximately 15 Watt unit finished in Progress Line blue paint, with TPL style red plastic knobs. They were purchased primarily by towing companies, taxi operators and small businesses which typically had just one or two mobiles, such as plumbing and electrical contractors. Although not that bad a design, the Pacer gained the reputation as an unreliable and poor performing radio, primarily because of the issue of hot tubes cracking the traces of the printed circuit boards. Nonetheless, many saw long years of service. There was no "standby" feature on the Pacer and the transistor power supply drew current at all times during operation, as well as being acoustically noisy, as was the crystal oven thermostat which made a "plink-plonk" sound at regular intervals. This was probably not an issue in a vehicle such as a tow truck, where the engine would be running at all times and rather noisy itself. There were no UHF Pacers, the equipment was made in low and high bands only, as well as in an attractive tabletop base station of totally different appearance. Few Pacers have survived.

Photo courtesy Ben Kittredge WA1PBR

Accent 450 (1961-1964)

The Accent 450 was a strange and unique UHF radio using tubes mounted on printed circuit boards as on the Pacer, with thick anodized aluminum heat sink-shields for the transmitting tubes attached to the sidewalls of the case. It was all vacuum tube type other than the transistors in the power supply. The receiver front end made use of a 1N21 UHF cartridge mixer diode. Sensitivity was relatively poor, but comparable to competitive equipment. The Pacer transmitter made use of a new, expensive and rather unreliable (in my opinion) Amperex glass UHF tube, type 7377. These tubes were short lived in actual use and it was unusual to find an Accent 450 in service which would produce more than a few Watts, if that. The odd control head of the Accent contained the speaker and could be mounted either on the front of the radio itself or remotely, using an extension cable. Not many Accents were made and they seem to be regarded as an even worse failure than the TPL. The Accent 450 had no provision for a locking tray or case, and the lid was a flimsy steel plate. The Accent 450, as its name suggests, was made only in a UHF version. Few Accent 450's have survived. Local examples have been refugees from the Port of Oakland, California.

Shown below is an example of an

Accent 450 configured for front-mount operation, in the museum room at the

Harris (GE) facility in Lynchburg. Photo courtesy Mark Cobbeldick

VOICE COMMANDERS I, II and III (1961-65)

The Voice Commander was GE's first hand-held VHF FM two way radio, introduced in July, 1961 and replaced the Progress Line pack set (which in late versions contained sections identical to the TPL mobile receiver.) The Voice Commanders II and III were fully solid state with Germanium transistors, while the Voice Commander I used subminiature wire-lead tubes for the transmitter power amplifier. The fully solid state Voice Commander, the II series, was in production by September, 1962. Coming from the same design studio as the TPL, Accent 450 and Pacer, the Voice Commanders were also considered ugly failures for many reasons. The Voice Commander was a strange all plastic blend of the properties of a pack set mated to that of a hand-held radio with perhaps the worst features of both! But they did work. Introduced in July, 1961.

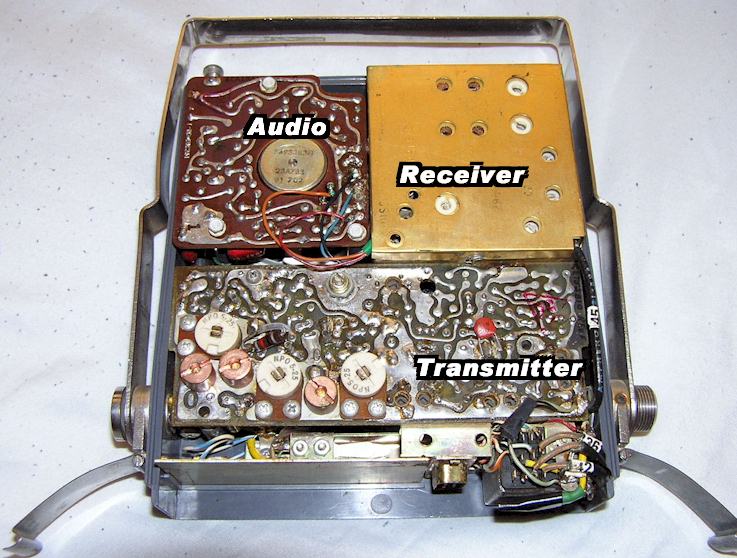

The push-to-talk button on the Voice Commander is in the front center of the unit, requiring both hands to hold the radio up and talk into it. There was also a remote microphone which plugged into a peculiar proprietary 3-pin connector on the left side of the carrying handle, on the III Series. The II and I series did not offer this option. The telescopic antenna could easily contact the grounded carrying handle, blowing the output transistors in the transmitter if the radio were on the air at the time. The large battery pack of the solid state Voice Commanders contained many sub-C nickel cadmium cells in a series-parallel arrangement. Although provided with a two channel switch, nearly all Voice Commanders were single channel, and most seem to have been wide band. The Voice Commander receiver was assembled from several modules encased in brass sheeting, while the transmitter was a single circuit board. See photo below. Power output was roughly one watt.

The battery box was available as a rechargeable nickel-cadmium style (II and III) or a dry battery version, as shown below (I, II and III.)

The receiver of the Voice Commander was somewhat subject to overload and assorted severe cross-modulation and intermodulation-distortion issues in high signal strength areas. But it was otherwise trouble free.

There were no UHF Voice Commanders, and it is believed that few low band versions were built, if any. The Voice Commander was built from approximately 1960-65. Considering that Motorola's successful HT-200 "Handie-Talkie" was introduced in 1963, it is easy to see why the Voice Commander was utterly non-competitive, although it was available as a transistorized portable before the Motorola HT-200 was on the market. Many Voice Commanders were used by fire departments and civil defense agencies.

In hindsight it is easy to think that had GE assembled the Voice Commander into a small "lunchbox" style pack-set case similar to the Motorola PT300 sets, with a conventional separate microphone and standard antenna, it probably would have been very popular.

It is hard not to think that the years 1961-63 must have been bleak ones for GE, in that virtually all of their new product lines during this period, in my opinion, were rather peculiar looking if not ugly, and often unreliable.

Voice Commander III:

POCKET MATE (1964-1969)

The Pocket Mate was GE's first actual hand-held radio and designed to compete with Motorola's HT-200 which had been introduced in early 1963. The Pocket Mate is believed to have been introduced about 1964 and is much smaller than competitor Motorola HT-200. The Pocket Mate is almost as bizarre in appearance as the Voice Commander or the Accent 450 radios. A peculiar captive telescopic whip antenna was permanently attached, and flipped upwards on the side of the radio to a vertical orientation. The round speaker in the front center also acted as the microphone, a design flop repeated by many designers over and over again throughout the 1960's and into the early 1970's, including the Motorola HT220. A round push-to-talk button near the top on one side completed the strange appearance of this ugly two-tone radio. The Pocket Mate was made only in VHF versions and is rare. They were also made under Bell & Howell and Kel-Com brand names in a dark, solid gray color style. The Pocket Mate was the radio found in the possession of the Watergate burglars during the famous Nixon era Watergate debacle. Some were apparently also used by the Secret Service and various covert agencies, which in retrospect leads me to pity them a bit for having to use what I think is a silly looking radio. For reasons unknown, the Pocket Mate and its relabeled versions are very rare today.

PORTA MOBIL (Porta Mobil I) (1964-1974)

GE introduced the Porta Mobil in high and low band models in April, 1964, at which time it contained the industry's first fully solid state 10 Watt transmitter.

The Porta Mobil was a solid state pack set intended to replace the Progress Line series portable, rather than the Voice Commander, in that unlike the Voice Commanders, it is larger and has a metal housing. The top handle is a spring-loaded affair which pulls up when grasped, then retracts when released. I am thinking that perhaps there was a major design department employee change at GE about 1964, when the "silly" looking radios stopped being made.

The Porta Mobil is fully solid state with a power supply which is an up - converting DC-DC converter, bringing the battery or input voltage to 36 Volts for the transmitter power amplifier stage. The Porta Mobil is actually heavier than the Progress Line portable, but runs a nominal 18-20 Watts on low band and 12 Watts on UHF and high band. The speaker audio output is quite high compared to previous pack sets. The Porta Mobil, being a MASTR series radio, has a centralized metering jack. It uses all silicon transistors. This set was available in either battery powered portable configuration, DC only power supply operation for mobile use, or an AC power supply for base station operation.

There was a steel mobile mounting tray to allow mounting of the radio in a vehicle, and a remote mount industrial version was also available, after May, 1965, usually used as a motorcycle radio within an appropriate rear-fender weather housing. The standard model featured a microphone, but a handset version was available. Two frequencies were as many as normally available, although a four channel model was made. The Porta Mobil was available in low, high and UHF bands and was purchased in large numbers by forestry and fire departments, logging and industrial buyers. The motorcycle version is rare today, as apparently few were made. The Porta Mobil has no quirks and is generally regarded as a high quality, reliable radio, other than needing a higher than expected amount of battery power on transmit. The knobs are frequently found broken or missing, and they are one area where a bit better quality could have been applied. A "Porta Mobil II" was introduced in approx. 1973 to replace the original Port Mobil. This was an olive colored unit with a plastic frame and die cast front and back metal panels.

Porta Mobile Motorcycle and Industrial Extended Control Head

MASTR Series (1964-1973)

MASTR Professional

The MASTR Professional Series began production in late summer 1964 and totally replaced the TPL, Accent and Pacer series as well as the remaining Progress Line models. The MASTR Professional series was quickly added to by an economy version bearing no similarity, called the MASTR Executive Line. By the late 1960's there was also the Custom Executive, a dash mount radio, and several other MASTR sub-models.

MASTR Professional became to the 1960's what the Progress Line had been to the 1950's, and probably saved GE's mobile radio business from disaster. The "MASTR Pro" is generally regarded as one of the finest mobile radios made by any manufacturer during the period. Unlike the TPL, the MASTR Pro series returned to the philosophy of the Progress Line in terms of separate power supplies, receivers and transmitters made in long chassis "strips." Unlike the Progress Line, the MASTR Pro strips were tied together at the ends with a cast front plate and a rear mounting plate, with individual covers (top and bottom) on each strip with a gap between the strips. This is as opposed to the single large "drawer" housing as used on the Progress Line or the screwed-together modules of the TPL. As viewed from the front, the MASTR Professional series chassis are, from left to right, receiver, power supply, and transmitter. Accessory chassis were usually placed across the rear apron.

The MASTR Pro equipment was available for all conventional bands as well as export and special service bands, in many different power levels. The UHF Mastr 60 Watt series was not ready for production until January, 1965. There were many "specials" with assorted options such as more than four channels, multiple channel guard operation, dual receivers, dual receiver front ends, scan, etc.. One of the more famous "specials" is the Illinois State Police Radio Network, or "ISPERN" radio, recognizable by its red microphone and multiple pilot lamps on the control head representing the channel in use.

The initial MASTR Pro series featured a solid state receiver with 2 Watts of audio, and a hybrid transmitter containing a solid state exciter and miniature and Compactron tubes in the power amplifier section. Up to four frequencies were available on the standard boards, and multiple channel models were available on special order for more than four channels. Later receivers were brought up to five watts of audio power output, and the last series used TCXO oscillator modules on VHF and UHF. Like the Progress Line, the "strips" from the MASTR Pro series could also be used in base stations, of which there were several configurations. MASTR Pro mobiles could have the control head mounted directly to the front of the rather large radio assembly, or used under the vehicle dash as was most commonly done. The early control heads were made of die cast metal while the last series were gray molded plastic. All of the MASTR microphones were Shure plastic housing types made for GE with a unique housing design.

By the late 1960's GE offered fully solid state versions called the MASTR Imperial and MASTR Royal Professional, to compete with Motorola's Motran series. These last-generation MASTR Professional radios typically used TCXO modules for frequency stability, called ICOMs in GE parlance, and were rather cutting-edge in design. They were and are uncommon.

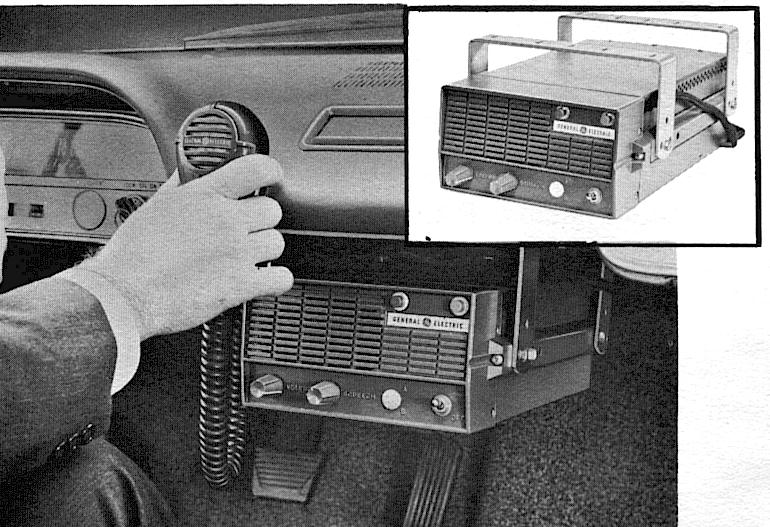

GE's advertising often showed the MASTR Professional as a front mount configuration, although the arrangement was so massive (much larger than the TPL) that few were ever configured that way.

There were two styles of speaker; one is as shown below with an all plastic front housing, and an earlier design with a perforated aluminum screen and a cast metal front housing. It is presumed that the change to a plastic speaker housing occurred at the same time that the control heads changed to plastic housings. There were also many custom control head faces made for special customers; the typical generic control head is the only one shown here. A "scan" head was also manufactured, which contained a four channel scanner in a deep housing.

All of the MASTR Professional heads contain a "standby" position on the power switch, which de-energizes the transmitter filaments to save vehicle battery power when there is no need for instant transmission capability, allowing the vehicle engine to be shut off for extended periods of monitoring.

The Mastr Professional series, based on serial number tags, seems to have still been in production through 1973 although the Mastr II was also being sold by 1970.

MASTR Executive (1965-1973)

The MASTR Executive was a cheaper alternative to the Professional series but enjoyed an equal reputation for reliability and durability. It was introduced in December, 1965 for VHF high and low bands, with a UHF version following approximately two years later. The receiver chassis of the Executive is a metallized plastic, and the transmitter is a hybrid design similar to the Professional series, using Compactron style tubes and conduction heat-sinking. The Executive radio is in a unitized package about 1/3 the size of the Professional, but was available with fewer options. The Executive was available with a small control head mounted to the front of the mobile drawer, where the control cable connector would normally be, or a separate dash mounted control head. Executives were very popular with RCC organizations and budget-minded customers. As with the Professional series, the last generations of the Executive had fully solid state transmitters and TCXO modules, and were referred to as the Royal Executive. The Executive series was available in all bands and several power levels. The Executive control heads were a cheaper design than the Professional, and featured no squelch control, instead having only a "Monitor" white pushbutton.

The Executive was a reliable, relatively trouble-free radio, despite its somewhat "cheap" construction.

Unlike the MASTR Professional, which requires a heavy mounting "tray," the bottom half of the Executive mobile housing has holes and a raised boss to allow it to be used as the mounting platform.

Both the Professional and Executive series would be replaced in the 1970's by the MASTR II and Executive II series radios, respectively, of substantially different design, with remaining stocks of both product being sold through approximately the end of 1973.

Below is a typical example of

the Executive mobile drawer, from 1967.

Executive series accessory

group. Note that the microphone hang-up clip was not normally located on

the control head; this was a customer-performed modification.

Ver. 9/5/2023 © Geoffrey C. Fors 2008 All rights reserved